DIY Laser Cutting: How to Work with Smart Fabrics

Imagine creating intricate designs on fabric with flawless precision—no frayed edges, no uneven cuts. What if your tools could transform your vision into reality effortlessly? This is the promise of modern technology in crafting.

Using advanced machines, you can achieve clean, sharp edges that elevate your projects. Whether it’s cotton, denim, or other materials, the power of precision tools ensures vibrant, professional results every time.

This blend of innovation and sustainability opens endless possibilities. It’s not just about crafting—it’s about expressing creativity while embracing eco-friendly practices. Ready to explore how technology can redefine your fabric projects? Let’s dive in!

Overview of Laser Cutting in the Textile World

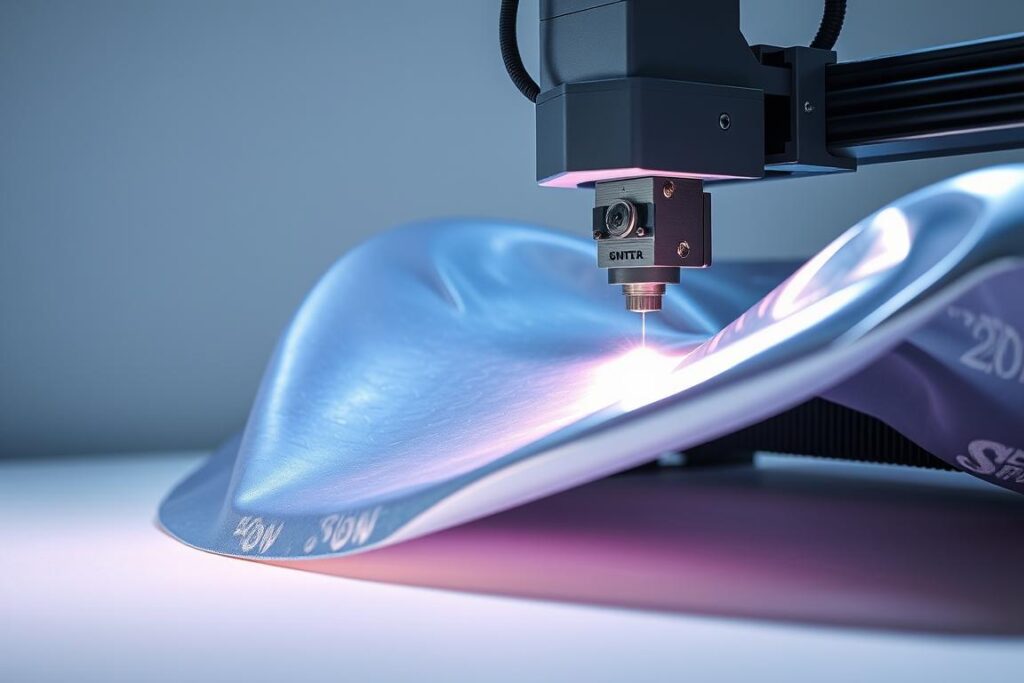

From intricate patterns to flawless edges, technology has reshaped fabric design. The textile industry has embraced laser cutting as a game-changer, offering unmatched precision and efficiency. This process allows creators to achieve detailed designs without physical contact, preserving delicate materials like cotton and polyester.

Modern laser machines use focused beams to cut and engrave with incredible accuracy. This eliminates fraying and ensures clean edges every time. Whether it’s denim for fashion or glass for decorative pieces, the power of this technology shines through.

Automation plays a key role in enhancing the process. Integrated software controls the machine, reducing errors and saving time. This not only boosts productivity but also minimizes waste, making it a sustainable choice for the textile industry.

“Laser cutting has redefined precision in textile design, offering endless creative possibilities.”

From custom clothing to intricate accessories, the applications are vast. The ability to laser engrave adds another layer of creativity, allowing for unique patterns and textures. This blend of innovation and sustainability is transforming the way we approach fabric projects.

DIY Laser Cutting: How to Work with Smart Fabrics

Ever dreamed of turning simple fabric into stunning masterpieces? With modern tools, it’s easier than ever! Advanced machines bring precision and creativity to your fingertips, making every project a joy to complete.

Setting up your own projects at home is simpler than you think. User-friendly controls and smart systems guide you through the process. Whether you’re working with cotton, denim, or other materials, these tools ensure clean edges and vibrant results.

Precision is key. A high-quality machine allows you to engrave and cut with unmatched accuracy. Software adjustments let you tweak designs for the perfect fit. This level of control ensures your creations are always top-notch.

“Innovative tools empower you to bring your vision to life, one layer at a time.”

Experiment with different fabrics and designs to discover new possibilities. Layered techniques add depth and texture, enhancing the final quality. The power of these tools lies in their ability to transform ideas into reality effortlessly.

Ready to take your projects to the next level? Dive into the world of advanced laser cutting and engraving. With the right tools, your creativity knows no bounds!

Essential Equipment and Machine Features for Fabric Laser Cutting

Unlock the full potential of your fabric projects with the right tools. Modern laser machines are packed with features designed to enhance precision and efficiency. Let’s explore the key components that make these machines a must-have for any creative enthusiast.

A through table is a game-changer. It allows for seamless processing of roll materials, ensuring smooth cuts every time. This feature is especially useful when working with large-scale projects or continuous feeds of fabric.

Dual laser heads, or duos, take productivity to the next level. By working simultaneously, they reduce processing time while maintaining accuracy. This is perfect for intricate designs or high-volume projects.

Conveyor systems and fabric unwinders ensure a steady feed of material. These components eliminate manual handling, making the process smoother and more efficient. Whether you’re working with leather or synthetic materials, these features guarantee consistent results.

“Integrated cameras are a game-changer, offering precise edge detection and design overlay for flawless results.”

Flat beds are another essential feature. They provide a stable surface for processing large rolls of fabric, ensuring even cuts and minimal waste. This is ideal for projects that require precision on a grand scale.

Inert gas blowing systems add another layer of quality. They prevent yellowing or burning, preserving the integrity of your fabric. This feature is particularly useful for delicate materials like silk or polyester.

With these advanced features, your creative possibilities are endless. From intricate engraving to flawless cuts, the right machine can transform your vision into reality. Ready to take your projects to the next level? The tools are waiting!

Preparing and Executing Your DIY Laser Cutting Projects

Ready to bring your creative vision to life with precision and ease? Let’s walk through the steps to ensure your projects are flawless from start to finish. Preparation is key to achieving professional results.

Start by selecting the right fabric. Natural materials like cotton and denim work well, but synthetics like polyester also offer unique benefits. Pre-wash and iron your material to remove wrinkles, ensuring a smooth surface for cutting.

Next, secure your fabric on the machine bed. Use adhesive spray or weights to keep it in place. This prevents shifting during the process, ensuring clean, precise cuts every time.

Adjust the machine settings based on your material. Factors like thickness and texture influence the power, speed, and focus needed. Always run a test cut on spare fabric to fine-tune these parameters.

“Taking the time to prepare ensures your project turns out exactly as envisioned.”

Safety is crucial. Ensure proper ventilation to avoid inhaling fumes, especially when working with synthetic materials. Keep a fire extinguisher nearby for added precaution.

If issues arise, troubleshoot promptly. Shifting fabric can be fixed by re-securing it, while unexpected burns may require adjusting the machine’s power settings. Patience and attention to detail go a long way.

With these steps, you’re ready to execute your project with confidence. Whether it’s a single layer or a complex design, your creativity will shine through every cut and engraving.

Tips, Tricks, and Common Pitfalls in Fabric Laser Cutting

Mastering fabric laser cutting requires a mix of skill, patience, and the right techniques. Whether you’re a beginner or a seasoned pro, these tips will help you avoid common mistakes and achieve flawless results every time.

Start by fine-tuning your machine settings. Adjust the power and speed to match the fabric type. For example, delicate materials like silk need lower power to prevent burning, while thicker fabrics like denim require higher settings. Always run a test cut to ensure accuracy.

Common pitfalls include misalignment, fabric movement, and overheating. To prevent these, secure your material with adhesive spray or weights. This keeps it steady during the process, ensuring clean, precise cuts. Overheating can be avoided by using proper ventilation and inert gas blowing systems.

“Attention to detail and regular maintenance are the keys to success in laser cutting.”

Regular maintenance is essential for optimal performance. Clean the machine’s lens and belts regularly to prevent dust buildup. Replace worn-out parts promptly to maintain precision. Keeping a detailed log of settings for different fabrics can save time and reduce errors in future projects.

Safety should never be overlooked. Always use protective gear and ensure proper ventilation to avoid inhaling fumes. Keep a fire extinguisher nearby, especially when working with synthetic materials. These precautions protect both you and your machine.

Here are some quick fixes for common issues:

- Use clamps or weights to stabilize shifting fabric.

- Adjust the focus and power settings to avoid frayed edges.

- Run a test cut on spare material to fine-tune your settings.

Mistakes are part of the learning process. Each error teaches valuable lessons, helping you refine your skills. With these tips, you’ll be well-equipped to tackle any fabric laser cutting project with confidence and creativity!

Conclusion

Transform your creative ideas into reality with precision and innovation. Modern tools like advanced machines bring unmatched accuracy to your projects, ensuring clean edges and vibrant results every time. Whether you’re working with fabric, leather, or other materials, these systems elevate your craft to professional levels.

Embrace the convergence of creativity, technology, and sustainability. By experimenting with different settings and materials, you can discover your unique style. Overcoming common challenges leads to improved quality and endless innovation in every project.

Join a community of makers who share your passion. Exchange tips, celebrate successes, and learn from each other. The industry is evolving, and now is the perfect time to dive in and explore the possibilities.

Ready to take your projects to the next level? With the right tools and a bit of creativity, there’s no limit to what you can achieve. Start your journey today and let your imagination shine!